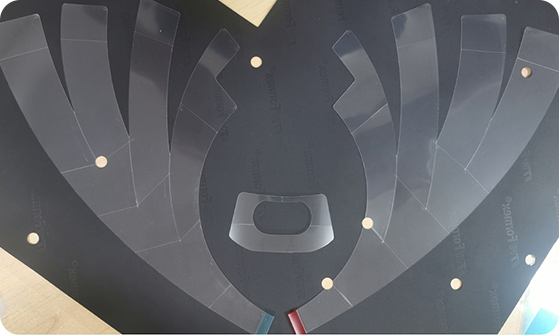

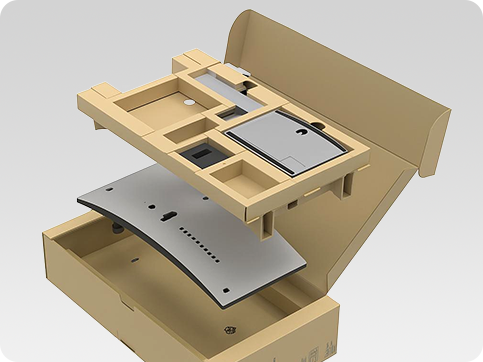

We have a team that combines artistic creativity with printing engineering expertise. They are not only shapers of visual aesthetics but also masters of printing processes and material properties. Driven by the mission of “Turning Designs into Reality,” the team transforms client ideas into high-value printed products that are visually impactful, functional, and innovative—serving as a vital bridge between creativity and manufacturing.

Team members hold certifications including Adobe Certified Experts, G7 Color Specialists, and Packaging Designer Qualification Certificate. They have also been awarded prestigious honors such as the iF Design Award, Pentawards, MUSE Design Awards, and Red Dot Award, among others in China’s printing and design competitions.